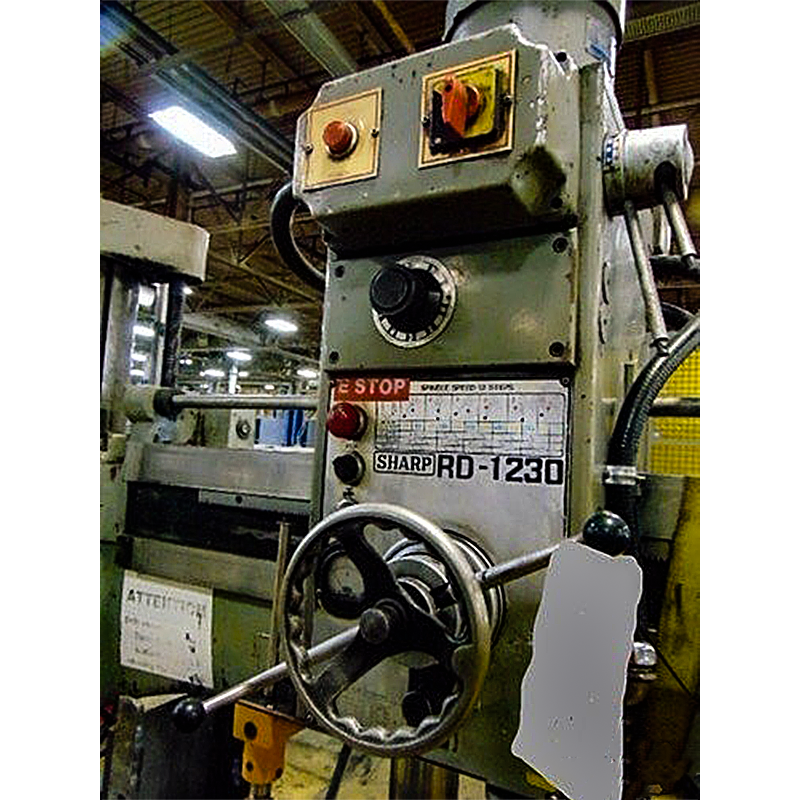

General view

Description

This is a great Radial Drill Press for your shop.

specification

| Maximum distance of main wheelbase column | 4' |

| Column diameter | 11.813" |

| power | 5 hp |

| Spindle speed | 1,500 RPM |

| aspect | 39"W x 80" L x 89"H |

| weight | 4,950 lbs. |

equip

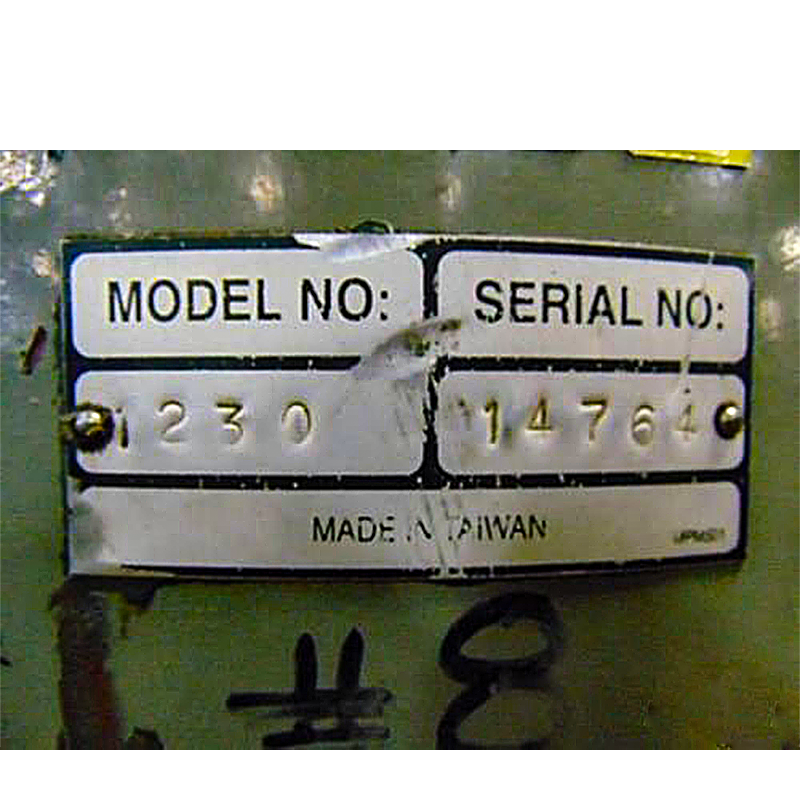

4' x 12" SHARP Model RD-1230 RADIAL ARM DRILL PRESS

New 2000

This is a high performance machine ideal for drilling, tapping , boring, reaming, lapping, screwing, counter boring, spot facing, and much more, on materials such as cast iron and steel.

Features

12” column diameter

MT#4 spindle, 5 HP motor

48” column to spindle center

Drilling: 2.18” cast iron, 1.62” steel

Boring: 4.75” cast iron, 3.37” steel

Hardened and ground arm slide ways and gears

Double tube column design to increase rigidity

Arm elevation controlled by electric motor

Manually operated arm, head, clamping

Safety device prevents arm from dropping even when bronze nut is worn out

Spindle depth setting with automatic kickout

Auto reverse tapping function

T-slots and drain channels on box table

Specification sheet

Specs:

Diameter of column: 11.81 in.

Distance from column surface to spindle center, max.: 48.5 in.

Distance from column surface to spindle center, min.: 13.37 in.

Travel of spindle head: 35 in.

Distance from base surface to spindle end, max.: 54 in.

Distance from base surface to spindle end, min.: 19.37 in.

Elevating height of arm: 2.88ft.

Effective area of table: 27.62 x 19.62 x 15.75 in.

Dimensions of base: 67.68 x 27.93 x 6.5 in.

Taper hole in spindle: MT #4

Stoke of spindle: 9.87 in.

R.P.M. of spindle (rpm range x steps): 44-150 x 12 steps

Feed of spindle (1PR x steps): 0.002-0.006 in. x 3 steps

Main motor (HP): 5 HP (2 speed motor)

Elevating motor (HP): 1 HP

Clamping motor for column and gear-box (HP): 1 HP

Clamping motor for arm (HP): 1 HP

Coolant pump (HP): 0.12 HP

Machine height from floor, max.: 9.12ft

Measurement (LxWxH): 6.66 x 3.25 x 7.41 ft.

Approximate shipping weight: 4,950 lbs.

Cast Iron

Drilling: 2.18 in.

Capacity Tapping: 1.5 in.

Boring: 4.75 in.

STEEL

Drilling: 1.62 in.

Capacity Tapping: 1 in.

Boring: 3.37 in.

TOTAL POWER CONSUMPTION

220V: 8 KVA/25 amps

440V: 8 KVA/12.5 amps

STANDARD ACCESSORIES:

Box table

Coolant system

Work light

Express can be sent to the United States, Vietnam, Saudi Arabia. If you are from another country, please contact: hongqiuhuang679@gmail.com

Products and services

Extensive product inventory

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

Professional testing and evaluation

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Excellent after-sales service

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

Reviews

There are no reviews yet.