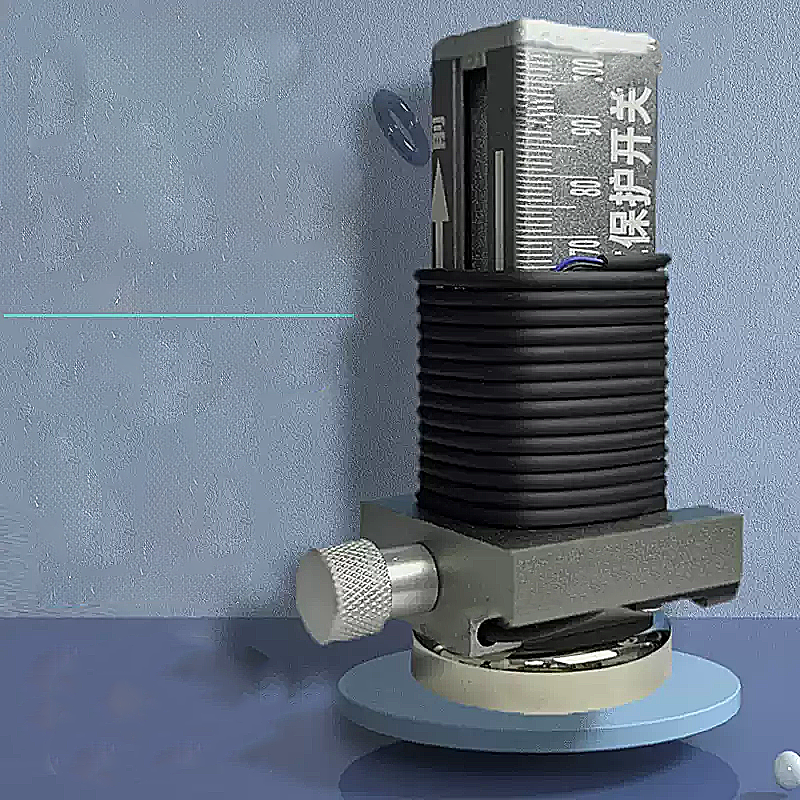

Injection mold thimble protection switch Adjustable thimble induction switch strong magnetic reset switch controller

$50.00

Parameter information

| Brand |

| Color classification |

| Other homes |

| D48 standard model,D48 special model |

Function Introduction

The injection molding machine mold ejector pin reset protection switch is a newly designed product. Its working principle is to use a detection switch to sense the mold ejector pin plate. The detection switch does not need to contact the ejector pin plate and adopts an inductive method. Just attach the protection switch to the moving template of the injection molding machine and adjust the sensing position. The protection switch signal can be used alone or connected in series with the injection molding machine ejector pins to use multiple signals. As long as one of them does not sense, the injection molding machine will alarm and stop clamping. Only when the ejector pin plate is fully retracted and all signals are connected will the injection molding machine clamp and start production, greatly improving the safety of the mold.

Product Features

Induction detection

The switch does not touch the thimble plate

Stable production without shift

D48 super strong magnet

New upgrade, super magnetic force

Non-slip high temperature mold 200° is not afraid

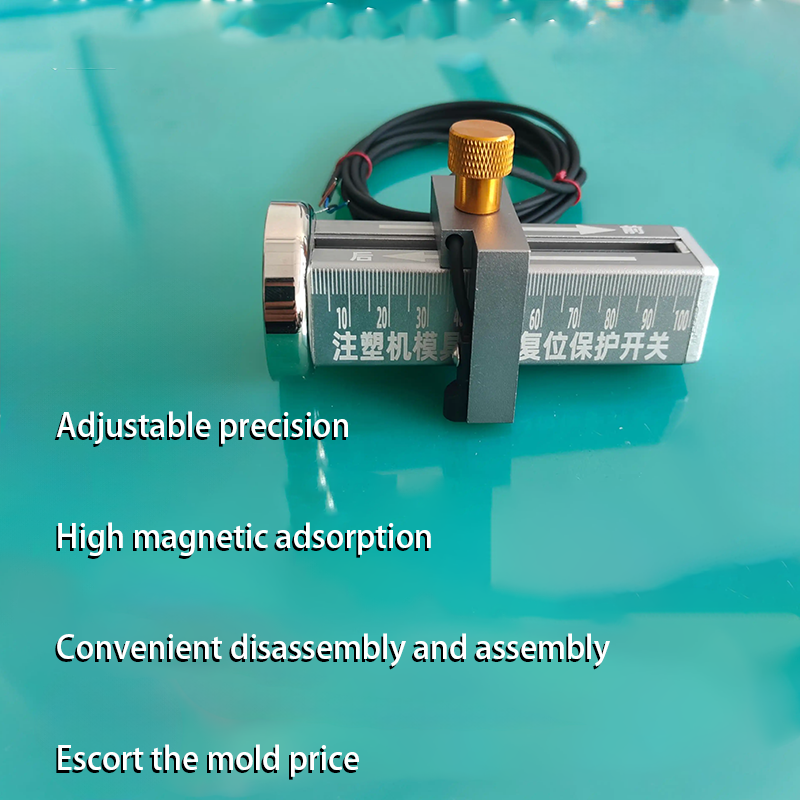

Adjustable precision

The position can be adjusted according to the size of the mold

High sensitivity, good flexibility

Imported chip

Induction switch adopts imported components

High detection accuracy, stable performance, long life

Injection molding machine mold protection artifact

Do a good job in every product

Examples of product use

The thimble is completely back in place

The thimble plate is not returned in place

The die thimble is returned to place

The sensor lights up and sends a signal to the machine

The injection molding machine will perform the mode-locking action

The die thimble plate is not returned in place

The induction light went off, and the machine didn't pick up the signal

Injection molding machine alarm to stop mode-locking action

Do you have such trouble?

The thimble burned to death

Break the mold

Mold repair time is slow

Delay in delivery

Each set of molds needs to be drilled for installation

Use trouble and easy to break

Solve all your problems

Escort the mold

The machine alarms if the thimble is not returned in place

The injection molding machine does not close the mold when it stops working

Strong magnetic adsorption, anti-slip shock resistance

No displacement in production

Only one injection molding machine should be installed

It doesn't have to be removed when not in use

| Color classification |

D48 standard model ,D48 special type |

|---|

Express can be sent to the United States, Vietnam, Saudi Arabia. If you are from another country, please contact: hongqiuhuang679@gmail.com

Products and services

Extensive product inventory

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

Professional testing and evaluation

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Excellent after-sales service

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

Reviews

There are no reviews yet.