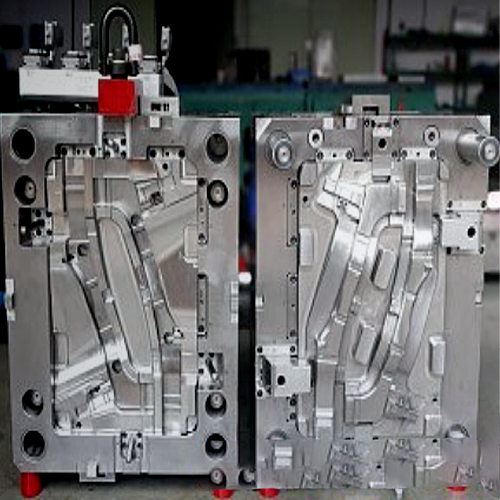

Mold design process:

Plan approval - preparation - machining - die set - mold core processing - electrode processing - mold parts processing - inspection - assembly - fly die - test - production and processing capacity: mold design, mold manufacturing and injection molding processing

The process of mold processing:

1. the bottom processing, processing quantity guarantee;

2. casting standard alignment, 2D, 3D profile margin check;

3.2D, 3D surface rough processing, non-installation non-working plane processing (including safety platform surface, buffer installation surface, pressure plate plane, side datum surface);

4. Alignment of the side datum surface to ensure accuracy before semi-finishing;

5. Semi-finishing 2D and 3D surfaces, finishing all kinds of installation faces (including limit block installation surface and contact surface, insert installation surface and back, punch installation surface, waste cutter installation surface and back, spring installation surface and contact surface, all kinds of travel limit working surface, oblique wedge installation surface and back), semi-finishing all kinds of guide faces and guide holes, Keep the residual finishing process reference hole and height reference surface, and record the data

6. Check and review processing accuracy;

7. Clamping process;

8. Before finishing, the datum surface of the process reference hole should be corrected and the allowance of the insert should be checked;

9. Finishing surface 2D, 3D, side punching surface and hole position, finishing process reference hole and height reference, finishing guide surface and guide hole;

10. Check and review machining accuracy.

Mold design process:

1. Daily maintenance of the mold, various moving parts such as thimble, row position, guide post, guide sleeve refueling, mold surface cleaning, water drainage, which is maintained every day during mold production.

2. Regular maintenance, regular maintenance including daily maintenance but also exhaust tank cleaning, trapped gas burning black level plus exhaust, damage, wear parts correction.

3. Maintenance of the appearance, paint the outside of the mold to avoid rust, when the mold is under the mold, the fixed mold should be coated with anti-rust oil, and the mold should be closed tightly when stored to prevent dust from entering the cavity.

Express can be sent to the United States, Vietnam, Saudi Arabia. If you are from another country, please contact: hongqiuhuang679@gmail.com

Products and services

Extensive product inventory

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

Professional testing and evaluation

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Excellent after-sales service

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

Reviews

There are no reviews yet.