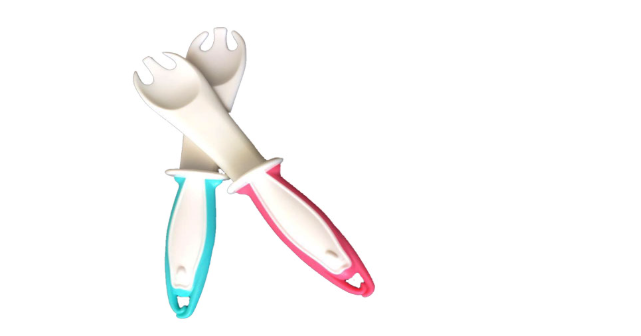

Children’s spork and spoon two-color plastic mold, two-color spork and spoon injection mold, high-quality plastic mold appearance parts

Children's spork and spoon two-color plastic mold, two-color spork and spoon injection mold, high-quality plastic mold appearance parts

Product introduction

Focus on two-color mold processing, manufacturing, injection molding, assembly and other one-stop services, the products involve digital electronic two-color mold, children's tableware two-color mold, instrument two-color mold and other two-color mold.

Children's tableware - knife and fork, knife and fork using ABS raw materials, safe and non-toxic, fork handle adhesive using TPE, the whole knife and fork and adhesive no section difference, batch front phenomenon, can not see the waterline so that children love. Beautiful appearance, good feel, comfortable and soft, loved by children.

Product display

Mold customization process

1. Analyze the product molding process, mold structure and production process. Ensure mold life to meet customer requirements

2. Design complete mold structure and machining parts, and put forward assembly requirements and injection molding process requirements

3. Fully analyze the appearance quality defects of plastic parts (such as shrinkage, etc.) or mold structure problems (such as parting surface setting, gate setting, mold life cannot be guaranteed, etc.) before opening the mold

4. Mold appearance: Mold appearance must ensure no rust, no impact, no defects and other module defects

5. Mold transportation: Mold transportation must be installed with mold locking sheet, solid packaging, rust prevention

6. Mold information: At the same time of mold delivery, provide a complete mold list and mold maintenance reference materials

Injection molding workshop

Precision workshop

Precision workshop

First, before each mold transfer, whether it is out of the country or abroad,

We'll paint them with anti-rust paint and put them in solid export wooden cases. Our wooden cases are all up to export standards.

2. Before loading, we put the wooden box on the wooden pedal and wrap it with transparent plastic protective film to avoid the mold from getting damp and play a role in fixing the product and waterproof, so as to ensure that the product can safely reach the destination.

Express can be sent to the United States, Vietnam, Saudi Arabia. If you are from another country, please contact: hongqiuhuang679@gmail.com

Products and services

Extensive product inventory

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

We have an extensive stock of used injection molding machines, covering a wide range of brands, models and specifications. Whether you need a small experimental injection molding machine or a large industrial production injection molding machine, we can provide you with the right choice.

Our products include but are not limited to monochrome injection molding machine, two-color injection molding machine, silicone injection molding machine, etc., to meet the diverse needs of different customers.

Professional testing and evaluation

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Every used injection molding machine that enters our inventory is rigorously tested and evaluated. Our technical team uses professional testing equipment and tools to conduct a comprehensive inspection of the mechanical structure, electrical system, hydraulic system, etc., to ensure the performance and safety of the equipment.

We also provide a detailed evaluation report for each piece of equipment based on its age, maintenance and performance, so that customers can clearly understand the actual condition of the equipment.

Excellent after-sales service

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

We not only provide high-quality used injection molding machines, but also provide customers with a full range of after-sales service. Including equipment installation and commissioning, training guidance, maintenance and so on.

We have a professional after-sales service team, ready to provide customers with technical support and solutions. We promise to respond within [X] hours after receiving a customer's service request to ensure that the customer's production is not affected.

Reviews

There are no reviews yet.